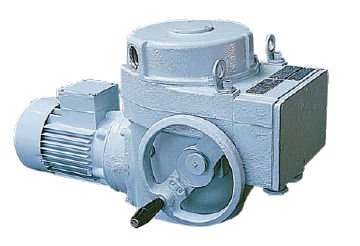

MOA (52 020 - 52 026, 52 029)

Electric rotary multi-revolution actuators for nuclear power plants - Outside containment

Electric rotary multi-revolution actuators for nuclear power plants - Outside containment

| MOA | ||||||||||||||

| Type number | 52020 | 52021 | 52022 | 52024 | 52025 | 52026 | 52029 | |||||||

| 20-63 | 63-160 | 160-250 | 160-630 | 630-1250 | 1250-2000 | 10-30 | ||||||||

| Tripping force [kN] | ||||||||||||||

| Adjusting time [s/90°] | ||||||||||||||

| Position-changing velocity | [min-1] | 9-40 | 9-100 | 9-80 | 16-100 | 45-63 | 32 | 9-40 | ||||||

| [mm/min] | ||||||||||||||

| Working stroke | [°] | |||||||||||||

| [ot] | 2-250 | 2-250 | 2-250 | 2-240 | 2-240 | 1-100 | 1,5-38 | |||||||

| [mm] | ||||||||||||||

| Supply voltage | 1x 230 V, 50 Hz | |||||||||||||

| 24 V, 50 Hz | ||||||||||||||

| 1 x 110 V, 50 Hz | ||||||||||||||

| 3 x 230 / 400 V, 50 Hz | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Control | Two position On-Off | ✔ |

✔ |

✔ |

✔ |

✔ |

✔ | ✔ | ||||||

| Three position | ||||||||||||||

| Continuous | ||||||||||||||

| PROFIBUS | ||||||||||||||

| Position sensing | Resistance transmitter (R) | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Absolute | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Current transmitter (I) | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Position interrupt | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Torque-initated interrupt | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Manual actuation | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Explosion-proof design | ||||||||||||||

| Type of enclosure | IP 55 | IP 55 | IP 55 | IP 55 | IP 55 | IP 55 | IP 67 | |||||||

| Weight - depending on design (Al/cast iron) and on motor [kg] | 35-37 | 65-68 | 68 | 128-131 | 210-212 | 318 | 17 | |||||||

Electric rotary multi-revolution actuators MODACT® MOA are designed for remote control of special valves installed in attended areas of nuclear power plants with reactors VVER or RBMK. The type series includes 5 sizes of electric actuators with tripping torque from 20 Nm to 2000 Nm. The actuators are suitable for controlling sliding valves and valves with nuts. For valves, the pitch angle of thread of the spindle nut must not be higher than 5°.