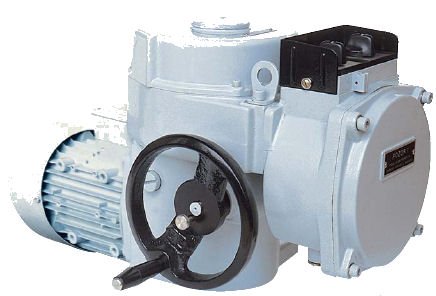

MOP (52 030 - 52 036, 52 039)

Electric Rotary Multi-turn Actuators - IP 67

Electric Rotary Multi-turn Actuators - IP 67

The MODACT ® MOP actuators have been designed for changing position of control devices by reversing rotary motion (e.g. slide valves and other devices for which they are suitable in their characteristics). A typical example of application is remote two-position or multi-position control of devices which are required to close tight in their end positions

| MOP | |||||||||||||||

| Type number | 52030 | 52031 | 52032 | 52033 | 52034 | 52035 | 52036 | 52039 | |||||||

| 20-125 | 63-160 | 160-250 | 250-500 | 320-630 | 630-1200 | 1000-2500 | 10-60 | ||||||||

| Tripping force [kN] | |||||||||||||||

| Adjusting time [s/90°] | |||||||||||||||

| Position-changing velocity | [min-1] | 7-80 | 7-145 | 7-145 | 16-100 | 16-63 | 45-100 | 20-40 | 9-40 | ||||||

| [mm/min] | |||||||||||||||

| Working stroke | [°] | ||||||||||||||

| [ot] | 2-250 | 2-250 | 2-250 | 2-240 | 2-240 | 2-240 | 2-100 | 1,5-38 | |||||||

| [mm] | ✔ | ||||||||||||||

| Supply voltage | 1x 230 V, 50 Hz | ||||||||||||||

| 24 V, 50 Hz | |||||||||||||||

| 1 x 110 V, 50 Hz | |||||||||||||||

| 3 x 230 / 400 V, 50 Hz | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Control | Two position On-Off | ✔ | ✔ |

✔ |

✔ |

✔ |

✔ |

✔ | ✔ | ||||||

| Three position | ✔ | ✔ | ✔ |

✔ |

✔ |

✔ |

✔

|

✔ | |||||||

| Continuous | |||||||||||||||

| PROFIBUS | |||||||||||||||

| Position sensing | Resistance transmitter (R) | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Absolute | |||||||||||||||

| Current transmitter (I) | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Position interrupt | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Torque-initated interrupt | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Manual actuation | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||

| Explosion-proof design | |||||||||||||||

| Type of enclosure | IP 67 | IP 67 | IP 67 | IP 67 | IP 67 | IP 67 | IP 67 | IP 67 | |||||||

| Weight - depending on design (Al/cast iron) and on motor [kg] | 27-28 | 41-54 | 45-54 | 90-97 | 97-99 | 206-211 | 304-309 | 17 | |||||||

Depending on their design, the MODACT® MOP Control actuators can be fitted with a position regulator, reversing contactors, overcurrent motor protection and the BAM electronic brake. They can be used to adjust control devices working in control systems, depending on the value of analogue input signal of the position regulator. They can also be equipped with reversing contactors only or with reversing contactors and the BAM electronic brake.