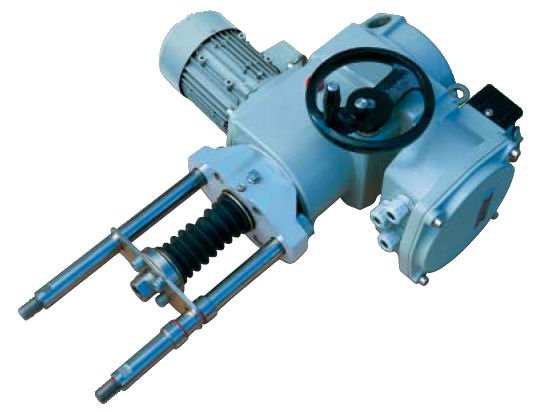

MTPED (52 441, 52 442, 52 443)

Electric linear thrust actuators with the electronic system - IP 67

Configurator of actuators MTPED

Electric linear thrust actuators with the electronic system - IP 67

Configurator of actuators MTPED

The MTPED actuators are based on MODACT MON actuator series. Moreover, they are designed with linear transmission unit for converting rotary motion into linear motion. An asynchronous motor drives, via a geared countershaft, the sun gear of a epicyclic gear unit enclosed in the supporting actuator box (power transmission). In the mechanical power control mode, the crown gear of a planet epicyclic gear unit is held in steady position by a self-locking worm gear drive. Alternatively, the handwheel, connected with the worm allows manual control to be accomplished even during motor operation without any risk of operator’s injury.

The actuator is controlled by built-in electronic circuits scanning the state of the actuator output shaft, output shaft torque, temperature of electric motor, value of supply voltage, and input signals. They are evaluated by the control program which, depending on pre-set parameters, controls output signals – state of output contact, output analog signal, control of electric motor, data communication with the superior control system.

The control elements are accessible after taking off the control box lid. For the actuators designated MTNED and for the actuators designated MTPED, the electric motors used have protective enclosures IP67. The complete actuator has the protective enclosure according to the electric motor used.

Electro-mechanical control board is replaced with the electronic system DMS2 or DMS2 ED. Both systems scan position of the output shaft and torque of the electric actuator by contact-free magnetic sensors. The sensor of the output shaft position is absolute and does not require any backup power supply in case supply voltage is disconnected during operation of the electric actuator.

Both systems can be set and monitored by a computer with controlling programme or manually without a computer. The more simple system DMS2 ED substitutes electromechanical parts and/or provides for controlling the electric actuator by input analog signal as in the version Control. The system DMS2 enables the electric actuator to be used for two-position and three-position regulation or to be connected to the industrial bus bar Profibus.

| MTPED | ||||

| Type number | 52 441 | 52 442 | 52 443 | |

| Tripping force [kN] | 5-25 | 11,5-25 | 25-63 | |

| Adjusting time [s/90°] | ||||

| Position-changing velocity | [min-1] | |||

| [mm/min] | 45-200 | 27-125 | 45-155 | |

| Working stroke | [°] | |||

| [ot] | ||||

| [mm] | 10-100 | 10-100 | 20-120 | |

| Supply voltage | 1x 230 V, 50 Hz | ✔ | ||

| 24 V, 50 Hz | ||||

| 1 x 110 V, 50 Hz | ||||

| 3 x 230 / 400 V, 50 Hz | ✔ | ✔ | ✔ | |

| Control | Two position On-Off | ✔ | ✔ | ✔ |

| Three position | ✔ | ✔ | ✔ | |

| Continuous | ||||

| PROFIBUS | ✔ | ✔ | ✔ | |

| Position sensing | Resistance transmitter (R) | |||

| Absolute | ✔ | ✔ | ✔ | |

| Current transmitter (I) | ||||

| Position interrupt | ✔ | ✔ | ✔ | |

| Torque-initated interrupt | ✔ | ✔ | ✔ | |

| Manual actuation | ✔ | ✔ | ✔ | |

| Explosion-proof design | ||||

| Type of enclosure | IP 67 | IP 67 | IP 67 | |

| Weight - depending on design (Al/cast iron) and on motor [kg] | 22 | 33-45 | 60-81 | |

The actuators MODACT ® MTPED are used for remote two-position or three-position control of valves by reciprocating linear motion. The actuators can also be used for other devices for which they are appropriate due to their performance and parameters. Using in special cases should be discussed with the manufacturer.